Get Your Custom Solution

Blueberry Cleaning and Grading Line

Apple powder remains; precise size; gentle care for delicate skin.

High-Efficiency Blueberry Grading Production Line

The Blueberry Cleaning and Grading Production Line utilizes microbubble physical cleaning technology to effectively remove surface impurities while preserving the natural bloom of blueberries to the greatest extent possible. The core roller grading unit, with precisely calculated gaps, achieves rapid and non-destructive size sorting, ensuring a high degree of uniformity in fruit specifications. It is an essential piece of equipment for high-end blueberry brands.

Why Choose GELGOOG's Sorter?

Engineered for Excellence, Designed for Your ROI.

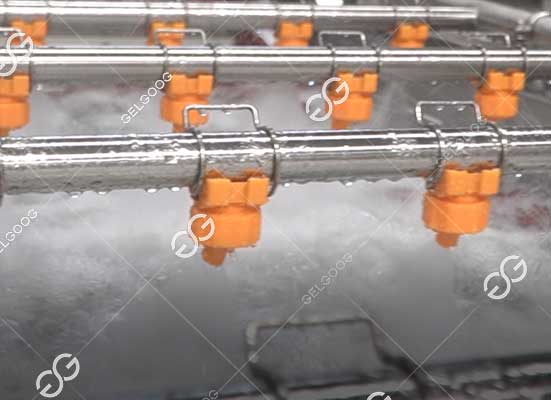

Gentle Cleaning

Blueberries enter the bubble washing machine via a water flow. The gentle physical force generated by the bursting bubbles effectively shakes off surface dust, impurities, and light deposits, while avoiding damage to the skin and washing away the precious natural bloom.

- Non-destructive cleaning preserves the bloom, maximizing the protection of the natural bloom on the blueberry surface, a key indicator of high-quality blueberries.

- Microbubbles work evenly across the entire blueberry surface, achieving a gentle clean without blind spots.

- During the washing process, lighter impurities such as branches and leaves float to the surface and are automatically removed.

Air Drying Process

After washing, the blueberries enter a customized air drying section. A filtered, even, and gentle low-temperature air curtain quickly and gently dries the surface moisture, ensuring the blueberries are completely dry.

- A dry surface is crucial for smooth rolling and accurate grading of the blueberries on the rollers.

- Rapid removal of surface moisture effectively prevents mold growth and extends shelf life.

- Improved Product Appearance: Dry blueberries have a more appealing appearance and convey superior quality.

Roller Grading

Blueberries enter the roller grading machine. The roller wall has multiple sets of precision grading holes, ranging from small to large. Blueberries tumble forward inside the roller, and when their size is smaller than the grading hole in their designated area, they fall into the corresponding collection trough, achieving precise diameter sorting.

- The roller rotates continuously, allowing for high throughput; the precise hole spacing ensures accurate grading and uniform specifications.

- Blueberries fall within the roller due to inertia, avoiding sharp, hard contact and resulting in an extremely low damage rate.

- The mechanical structure is mature and stable, suitable for 24-hour continuous production, and easy to maintain.

Blueberry Packaging

Graded blueberries of various grades are guided to designated buffer collection areas or directly connected to automated packaging equipment via flexible, food-grade conveyor belts or chutes.

- A strict physical separation design ensures complete separation of blueberries of different sizes and grades.

- The output end can seamlessly connect with various automated packaging machines to form a complete production line.

- The entire process employs cushioning and drop differential desig