Industrial-grade automatic apple waxing and polishing machines are specially designed systems designed to efficiently clean, wax, and polish apples, giving them a glossy finish ready for market. They are widely used in fruit processing plants, orchards, and cooperatives to enhance the appearance and shelf life of apples.

Key Features

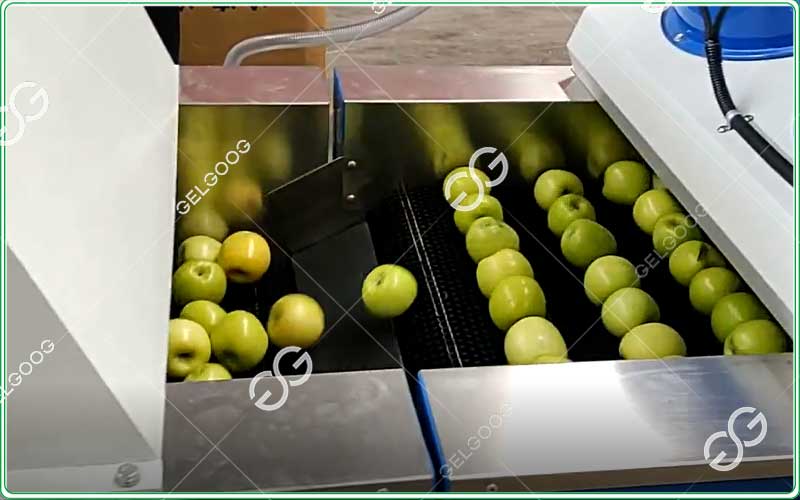

Integrated Process: Typically includes washing, brushing, waxing, drying, and grading. This ensures that apples are thoroughly cleaned, polished, and sorted by size or weight before packaging.

Process: High-pressure cleaning → Powerful airflow drying → Precision atomized waxing → Multi-stage flexible polishing → Infrared-assisted curing

- Waxing System: Edible wax is applied using a spray nozzle, typically controlled by a timer or PLC to ensure an even coating. Wax helps preserve freshness, prevents moisture loss, and enhances visual appeal.

- Polishing Mechanism: After waxing, a soft brush or roller polishes the surface of the fruit, enhancing its gloss without damaging the skin.

- Material: Most machines are constructed of food-grade 304 stainless steel for hygiene and durability. Capacity: Depending on the model and configuration, hourly output ranges from 3 to 10 tons.

- Automation: Fully automated system with touchscreen controls, variable-speed conveyors, and a grading unit for size/weight sorting.

Optional Accessories

Drying Section: Drying the waxed apples with air knives or fans.

Grading Unit: Sorting apples into grades based on diameter or weight.

Customizable Layout: The machine can be customized to suit your factory space and production needs.

Comprehensive Service Support

We not only provide high-performance equipment, but also offer full lifecycle support to ensure your production line continues to operate efficiently:

- Installation and Commissioning Services: Engineers provide on-site installation and commissioning services to ensure immediate operational operation.On-site operator training is provided to help your staff quickly master equipment operation.

- Technical Training and Operation Manuals: Operation manuals, maintenance guides, and troubleshooting manuals are available in both Chinese and English. Optional online or offline technical training covers daily maintenance, parameter adjustments, troubleshooting, and more.

- After-Sales Support: We provide 24/7 technical support with a response time of less than 12 hours, and on-site response within 48 hours for major issues.

- Spare Parts and Upgrade Support: We provide rapid access to genuine spare parts to minimize downtime.

Contact us for a service brochure and quote.

We offer customized solutions and turnkey engineering services tailored to your plant layout and production capacity requirements. Visit us for a test drive and personalized solutions.

Reviews

There are no reviews yet.