The onion sorting and grading machine utilizes advanced roller gap adjustment technology, specifically designed for the automatic size sorting of spherical root vegetables and fruits such as onions, potatoes, and citrus fruits.

This machine achieves precise, damage-free grading through a physical gap principle, making it a core sorting equipment in agricultural product processing, packaging, and distribution.

Onion Sorting Machine Working Principle

- Progressive Roller Conveyor System: The conveyor belt uses parallel rotating rollers. Onions move smoothly forward on the rollers and rotate naturally, ensuring that all surfaces of each onion have the opportunity to contact the grading gap.

- Adjustable Gap Grading Zone: The grading area is designed with a progressively widening gap; the gap between adjacent rollers gradually increases from the inlet to the outlet. Onions smaller than the current gap naturally fall into the corresponding collection chute.

- Automatic Discharge and Collection: Onions of different sizes are sorted and slide through the corresponding discharge chutes into collection boxes, packaging lines, or conveyor belts, achieving fully automatic continuous sorting operation.

Onion Grading Machine Core Advantages

- Precise Grading Effect: Through precise mechanical adjustment, it can achieve sorting into 3-8 size grades, with a grading accuracy of ±2mm, meeting the strict classification requirements of different specifications of onions in domestic and international markets.

- Zero-Damage Physical Sorting: Pure mechanical gap sorting principle, without complex sensors or optical systems, completely avoiding errors that may be caused by electronic equipment, and causing zero impact and zero damage to the onion skin.

- Efficient Continuous Operation: Single machine processing capacity can reach 1-5 tons/hour, stable and reliable for 24-hour continuous operation, especially suitable for large-scale centralized processing during the harvest season.

- Extremely Simple Operation and Maintenance: No complex electronic control system, robust and durable mechanical structure, very low maintenance costs, and operators can master it after simple training.

- Strong Adaptability Design: The roller spacing is manually/electrically adjustable, which can quickly adapt to the size sorting requirements of different varieties and origins of onions. Production changeover only takes 5-10 minutes.

Onion Roller Grader Frequently Asked Questions

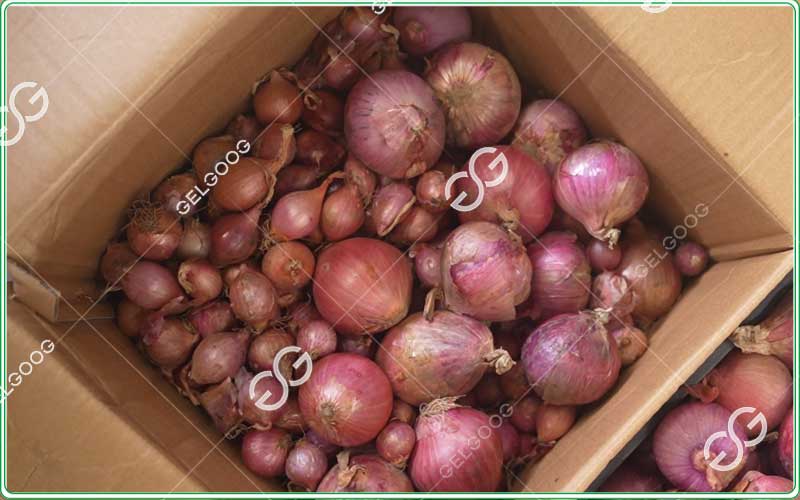

- Q: Can the machine sort different varieties of onions?

A: Absolutely. By adjusting the roller gap, it can handle various varieties such as yellow onions, red onions, white onions, and small onions (pearl onions), and can sort onions with a minimum diameter of 25mm. - Q: Will soil on the onions affect the sorting accuracy?

A: It will not significantly affect it. The rotating motion and appropriate vibration of the rollers will automatically remove most of the soil. For onions with a lot of soil, it is recommended to add a simple cleaning step at the front end. - Q: Is maintenance complicated?

A: It’s very simple. The main maintenance work involves regularly lubricating the bearings and cleaning the equipment surface. All maintenance points are designed in easily accessible locations.

Reviews

There are no reviews yet.