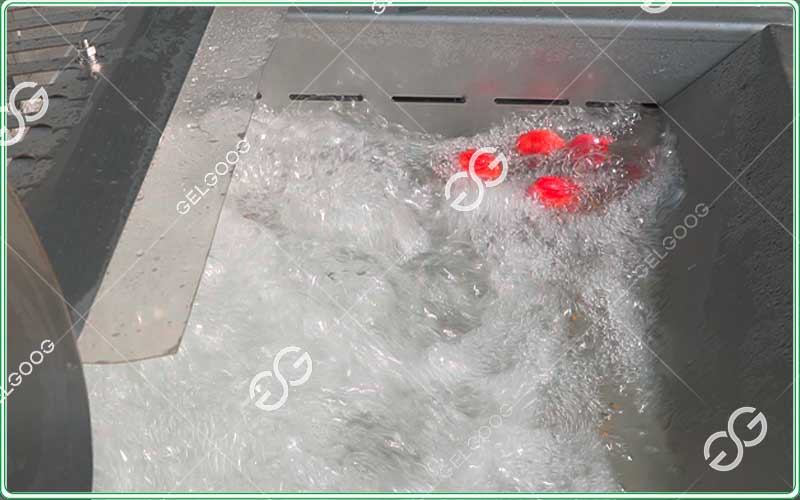

Our strawberry bubble washing machine is specifically designed to gently clean delicate berries such as strawberries. While efficiently removing surface impurities, it minimizes physical damage to the fruit, making it the ideal pre-processing equipment for strawberry processing plants, large farms, and food companies.

Our industrial strawberry washer features

- Bubble agitation for physical cleaning: Micro-perforations at the bottom of the equipment release a continuous stream of dense, fine bubbles. As the bubbles rise, they gently agitate the water flow, causing the strawberries to tumble and separate naturally in the water. This effectively removes surface dust, sand, pollen, and some pesticide residues, while avoiding skin damage and bruising caused by brushing or strong water jets.

- Water circulation for continuous cleaning: During the cleaning process, a double-layer filtration system is employed. Dirt and debris are carried into the filtration tank by the water flow; light impurities such as leaves and stems are carried away by the overflow, while heavier impurities such as sand settle automatically. The clean water is recycled, achieving a water saving rate of up to 70%, making it both environmentally friendly and economical.

- Food-grade safety design: The entire machine is made of SUS304 food-grade stainless steel, with no sanitary dead ends, complying with HACCP international food safety standards. The open structure allows for quick disassembly and cleaning, meeting the need for thorough cleaning after each day’s production.

Advantages of Our Gentle Fruit Washing Machine

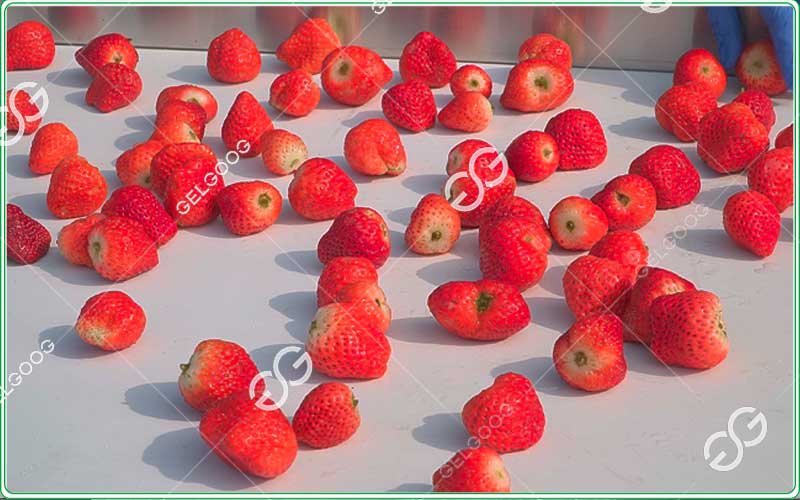

- Extremely low damage rate, guaranteeing profits: Traditional cleaning methods often result in strawberry damage rates exceeding 5%. Our bubble cleaning technology, through precise control of water flow and bubble intensity, can control the damage and stem loss rate of strawberries to below 1.5%, directly protecting your product value and profits.

- Significant cleaning effect, improving quality: The bubbles and water flow form a three-dimensional cleaning network, ensuring thorough cleaning without blind spots. After processing, the strawberries have a bright color and smooth surface, significantly improving product appearance and grade, whether for supplying the high-end fresh fruit market or for use as ingredients in frozen products, jams, or yogurt.

- High efficiency and stability, ensuring production capacity: Single-machine processing capacity can be customized according0 to needs (500-3000 kg/hour), easily handling the concentrated processing pressure during the harvest season. The robust industrial structure ensures that the equipment can operate continuously and stably for 24 hours, with a low failure rate and simple maintenance.

- Flexible Adaptation to Production Lines: Featuring a modular design, it can be easily and seamlessly integrated with upstream lifting machines, downstream air dryers, sorting machines, and quick-freezing lines, becoming a reliable link in your automated processing line.

Who needs this equipment?

- Strawberry Growers/Cooperatives: Used for commercial processing of fresh fruit, improving market quality.

- IQF (Individually Quick Frozen) Strawberry Processing Plants: As a key pre-processing equipment, ensuring clean raw materials.

- Jam, Juice, and Yogurt Fruit Pulp Producers: Obtaining clean raw materials to extend the shelf life of subsequent products.

- Large Supermarkets/Fresh Produce Distribution Centers: Establishing a standardized clean fruit processing workshop.

Frequently Asked Questions

Q: Is bubble cleaning really better than traditional drum or spray cleaning?

A: For delicate fruits like strawberries, the answer is yes. Drum friction and high-pressure spraying can easily cause skin damage, while bubble cleaning provides uniform, gentle buoyancy cleaning, ensuring cleanliness while providing optimal protection for the fruit.

Q: Can it remove pesticide residues?

A: This machine mainly efficiently removes physical impurities (mud, dust, etc.). It has some effect on removing water-soluble surface pesticide residues. For stronger pesticide residue degradation capabilities, an ozone water generator can be added to inject ozone water during the cleaning process for more thorough cleaning.

Q: Can it clean other fruits?

A: Absolutely. This equipment is also suitable for similar delicate fruits such as blueberries, raspberries, goji berries, and cherry tomatoes, offering multi-purpose functionality.

Take Action Now

Don’t let the cleaning process be a source of loss and quality uncertainty. A professional piece of equipment is the beginning of your large-scale, standardized production.

Step 1: Tell us your needs

Click the button below to get more detailed product information and technical solutions.

Step 2: Get a customized solution

Our engineers will contact you to provide customized solutions and transparent pricing based on your workshop layout and production capacity goals.

Reviews

There are no reviews yet.