These machines don’t simply soak produce in water. They employ a combination of physical and chemical principles to achieve a deep clean:

- Soaking and Softening: First, the produce enters a soaking tank, which helps soften and loosen stubborn dirt, impurities, and some pesticides.

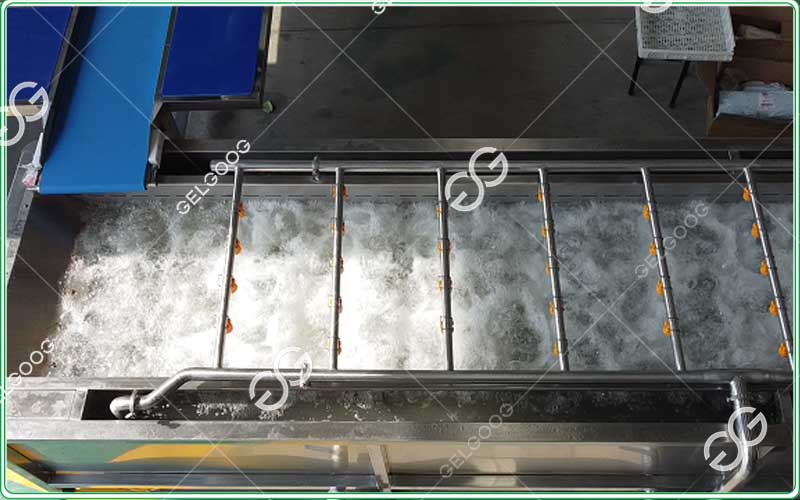

- Bubbling Cleaning: At the bottom of the tank, pipes release dense bubbles. As they rise, these bubbles rub and flush against the surface of the produce, effectively removing dirt trapped in wrinkles and crevices while being very gentle on the skin.

Brushing/Spraying:

- lBrushing: Suitable for root vegetables like potatoes, carrots, and sweet potatoes, or fruits with tough skin. The soft bristles rotate to provide friction and cleaning.

- lHigh-Pressure Spraying: A high-pressure jet of water is used to rinse the produce from all sides. This is particularly suitable for delicate produce like strawberries and leafy vegetables, removing residual pesticides and microorganisms.

- Peeling and Polishing (Optional): For some specialty products (such as potatoes, carrots, and apples), the cleaning machine can be equipped with a peeling or polishing function, using gentle friction to create a smoother, more attractive skin.

- Rinsing and Dehydration: Finally, the produce is rinsed with clean water and may pass through an air dryer (cold or hot air) to remove excess surface moisture, extending shelf life.

Why Are They so Effective? What Are the Benefits?

- High Efficiency: A single machine can process hundreds of kilograms to several tons of produce per hour, a feat unmatched by manual labor.

- Thorough Cleaning: It can reach crevices and recesses difficult to reach manually.

- Consistent Cleaning: The machine does not tire, ensuring consistent cleaning standards for each batch of produce.

- Microbial Reduction: It effectively reduces the number of pathogenic bacteria such as E. coli and Salmonella, complying with food safety regulations.

- Pesticide Residue Removal: When combined with food-grade cleaning agents (such as ozone and hypochlorous acid), it can significantly break down and remove pesticide residues from surfaces.

- Save labor costs: A single machine can replace a significant amount of manual cleaning work.

- Reduce product loss: Gentle cleaning methods (such as air bubble cleaning) protect the skin of fruits and vegetables better and reduce damage than harsh manual scrubbing.

- Increase product value: Clean, shiny produce is more attractive in the market and fetches a higher price.

Should You Buy One?

A fruit and vegetable cleaning machine is a worthwhile investment in the following situations:

- Large-scale production: You are a farmer, cooperative, or processor processing large quantities of produce.

- Quality requirements: Your products are destined for high-end markets, supermarkets, or export, and you have strict standards for cleanliness and safety.

- Efficiency improvements: You want to reduce long-term labor costs and increase processing speed.

How To Choose?

The key is to choose the most appropriate cleaning technology (air bubble, brush, or spray) based on the specific product type you are processing (soft berries or tough roots).